Custom Mil-Spec Defense Products

From the deepest oceans, to the most rugged terrain, to the depths of outer space, Titanium Fabrication has been involved in some of the most complex and technologically advanced projects for government and defense related industries.

The combined experience of our welders, craftsmen and machinists allows us to handle the most complex projects with ease. Rapid prototyping of parts involving all stages of fabrication can be handled under one roof, and our extensive array of local sub-vendors allows us to provide testing, stress relieving, finishing and expedited shipping services as well.

Titanium Fabrication has approved Fabrication Plans per MIL-STD-278, and can weld to the highest standards for U.S. Navy Shipboard Applications. We have NAVSEA approval for welding all grades of titanium, up to six inches thick, per the NAVSEA Technical Publication S9074-AR-GIB 010-278. We also have all the corresponding NDE procedures approved.

Click below for details on specific defense products we specialize in.

TiFab fabricates our defense projects in adherence to:

- NAVSEA S9074-AQ-GIB-010/248 (MIL-STD-248) — Requirements for Welding and Brazing Procedure and Performance Qualification

- NAVSEA S9074-AR-GIB-010/278 (MIL-STD-278) — Requirements for Fabrication, Welding and Inspection, and Casting Inspection and Repair for Machinery, Piping, and Pressure Vessels

- NAVSEA T9074-AS-GIB-010/271 (MIL-STD-271) — Requirements for Nondestructive Testing Methods

Welding Processes:

- GTAW (TIG)

- GMAW (MIG)

- SAW (Subarc)

- PAW (Plasma)

Certifications

- NAVSEA Tech Pub 278

- NAVSEA Tech Pub 248

- NIST SP 800-171 Compliant

- ITAR Registration

Custom Defense Products

Titanium Welded Assemblies

Titanium Fabrication has welded assemblies on every U.S. nuclear submarine and air craft carrier built in the last 20 years.

Learn More

Nickel Alloy Welded Assemblies

TiFab has been a trusted partner with the U.S. Navy shipbuilding contractors for over 30 years.

Learn More

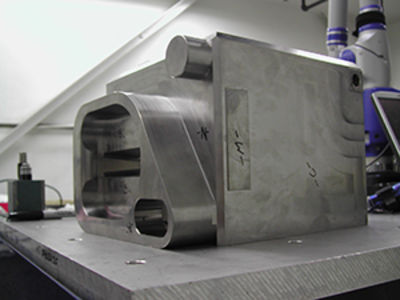

Machining of Custom Navy Components

In addition to our world renown welding expertise, TiFab also has best in class machining capability for titanium and nickel alloy marine components.

Learn More

Weld Repair of Castings & Rotating Equipment

TiFab has all the necessary TIG titanium and zirconium welding procedures approved for NAVSEA Tech Pub requirements, or for ASME code requirements.

Learn More